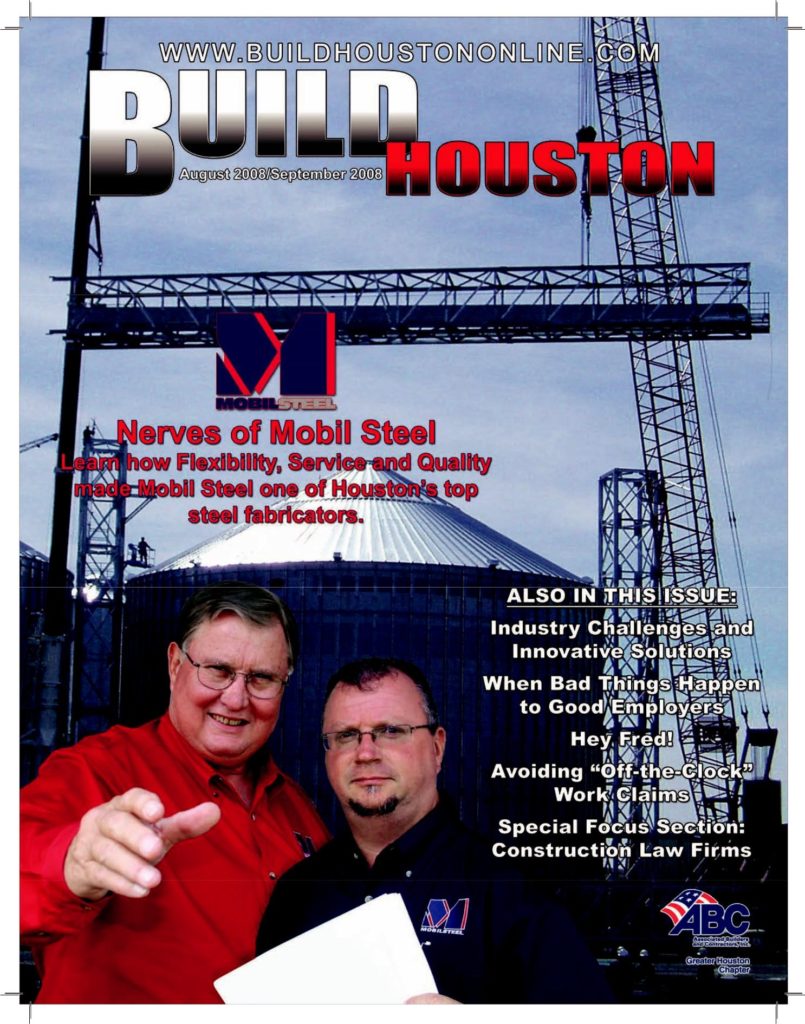

Nerves of mobil steel

Flexibility in Steel Projects

As the economy hints at recession, energy prices soar, and raw materials costs rise – such as steel’s 40 percent increase – companies are challenged to deliver value beyond pricing. Mobil Steel International, Inc., the 40-year-old steel fabrication business, meets the challenge by embracing customers and vendors as partners, demonstrating a “can do” assurance and trust.

“The customer is our partner,” explains Leonard A. Bedell, Mobil Steel’s President and CEO. “We pride ourselves on serving their needs. Projects and customers change, however, we remain true to customers and our core values: integrity, reliability, quality and flexibility.”

Mobil Steel fabricates steel to fit customer needs.

Flexible Operations

Mobil Steel builds and trains a team of employees with experience and skills to serve customers. General Manager Mark Scott is an example of the multi-skilled personnel who return to Mobil Steel and accelerate its development. Scott worked in the Mobil Steel plant while still in school, developing operational and leadership skills. Now a veteran manager in steel fabrication and erection, his vast knowledge helps operations better serve customers.

Following a failed ownership change ending in 2004, new management and investors directed the company’s recovery with emphasis on commercial building. Mobil Steel fabricated steel for schools, hospitals, and office buildings. As the company rebuilt its management team and skilled staff, they responded to changing energy markets and began fabrication for major projects in petrochemical, oil service and alternative fuels markets, such as ethanol, LNG, and biodiesel plants and related pipelines

Mobil Steel’s 8.5 acre site adjacent to Beltway 8 near Highway 288 provides convenient access and abundant capacity. Six bays and 80,000 feet of fabrication area under roof provide flexibility to meet customers’ schedule requirements.

“We developed great relationships and improved our plant’s skill set for doing commercial and industrial work,” Bedell relayed. “We also reinforced relationships with returning customers in refining and petrochemical markets as they expanded. We now serve commercial, energy sectors, refining and chemical projects.”

Reliable Partner

Mobil Steel has capacity to deliver multiple projects – six bays with 80,000 feet under roof fabrication area sit on 8.5 acres. When other fabricators cannot meet schedules, Mobil Steel utilizes its flexible capacity to meet customers’ requirements.

“Even when not awarded a bid proposal on a new project, we let companies know we are there to back up their fabrication and scheduling needs. We want them to know that we have experience, talent and capacity to deliver on time, and that we are flexible,” advocated Bedell.

“It works to our advantage. Several larger jobs in 2007 developed from jobs we initially were not awarded, generally due to scheduling or performance issues with fabricators selected. We secured future jobs by coming through for the respective projects’ completion success.”

Mobil Steel emphasizes long-term relationships. While others over-promise on delivery and capacity to perform, Mobil Steel strives to exceed expectations. Experienced employees forecast reasonable timetables, give accurate pricing and build a partnership to last.

“We are not going to promise a quick turnaround or cheap price to get business,” mentioned Scott. “Our relationships are built on trust and credibility. We deliver on our promises.”

Service & Quality

“We appreciate the trust that our employees, customers and vendor partners placed in us when we were going through tough times,” states Bedell. “We are loyal to those who believed in us and wanted Mobil Steel to succeed. Our vendors, bankers, investors and dedicated employees provided ingredients for a successful transition. We see opportunity to secure more work through loyal relationships and a stronger customer base.”

Mobil Steel repays that trust through community and business service. Employees volunteer with community clubs and little league, contribute to local charities and actively support ABC Greater Houston’s industry development and training. Mobil Steel employees and managers sacrifice additional time and effort to be quality certified by American Institute of Steel Contractors (AISC).

“We owe our customers extra value. We provide quality and reliable service job-afterjob,” Bedell stated. “Mobil Steel is proud to be one of few Houston area fabricators that have gone the extra step to meet stringent AISC certification.”

“Just like our logo, the AISC quality logo is a mark of excellence in the steel fabrication business,” Bedell emphasized.